Indefinite chilled cast iron roll is cast using such proportions of silicon, chromium, nickel and molybdenum that the working face is no longer completely white but contains a small amount of very finely distributed graphite flakes gradually increasing from face to core with corresponding decrease in the amount of carbide. The surface of these Rolls have chill with various alloys and are iron based. The matrix structure is pearlitic or bainitic depending on the content of alloys and its proportion. These rolls are to ensure minimum sacrifice of clear chill while achieving maximum functional depth. The transition from chill to graphite being smoother, the gradual change in hardness associated with the indefinite-chill structure allows deeper grooving. Thus indefinite chilled cast iron Rolls are superior in biting performance and have enough strength and resistance against thermal shock occurring at the time of accident in the rolling operation compared to clear chill Rolls. Rolls of this type have hardness up to about 70 Shore C can be grooved for use in roughing and finishing stands, for processing sections such as T-bars and U-sections, and for roughing and intermediate rolls of wire and rod mills resulting excellent performance in plate and section finishing.

Properties

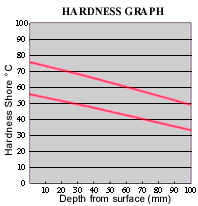

Hardness Graph

Chemical Composition (in %) & Mechanical Properties (1 MPa=1 N/Sq mm) of Indefinite Chilled Cast Iron Rolls:

| Element | C | Si | Mn | P | S | Cr | Ni | Mo | Uts(Mpa) | Bending strength of journal(MPa) | Barrel hardness in Sh C |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | 2.90 | 0.90 | 0.60 | 0.150 | 0.060 | 0.80 | 1.50 | 0.20 | 250 | 375 | 50 |

| Max | 3.50 | 1.30 | 0.90 | Max | Max | 1.20 | 3.00 | 0.40 | 450 | 700 | 75 |