Spheroidal Graphite Cast Iron (S. G. Iron) or Ductile Iron is considered as one of the most versatile roll materials now a days. It is produced by a small proportion of magnesium added to the melt as Nickel-Magnesium or alternative alloy, or as pure magnesium. In SG Iron Roll, the free carbon takes the shape of spheroids or nodules, thereby eliminating the notch effect of flake graphite and improving upon the mechanical properties of the cast iron. S.G. Iron Rolls are so superior in wear resistance to that of cast steel Rolls that they are specially adapted for roughing and intermediate plate mills and rod or bar mill roughers. As a result of the spheroidal form of the graphite, SG Iron Rolls are much stronger than rolls of the clear-chill type and the gradual fall in hardness is an added advantage.

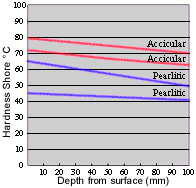

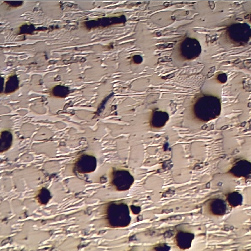

As such, these rolls are particularly suitable for skelp and strip mills, also Bar Billet Mills, and are being increasingly used for other applications. The structure of SG Iron rolls consists of transformed austenite (pearlite) eutectic carbide and spheroidal graphite. Spheroidal Graphite Iron Rolls may have a pearlitic matrix or, if relatively large amount of alloy elements are present the structure may be acicular or martensitic.These are specifically good for small section and flat rolling. There is also some use of pearlitic SG Iron Rolls in conditions in which the first essential is toughness, rather than wear resistance, e.g. rolls for heavily loaded roughing stands. In many cases SG Rolls with an acicular matrix is preferred, because of its wear-resisting qualities. To this end, the iron is alloyed with Nickel and Molybdenum, to permit formation of an acicular structure in the as-cast condition. These rolls are most suitable for heavier section where added strength and depth of hardness are required. Sand-cast acicular SG iron is employed for certain special-purpose rolls, e.g. pilger rolls.Spheroidal Graphite or Ductile Iron Rolls (SG Iron Rolls) are generally used in Roughing and Intermediate stands of structural and section mills as well as finishing mill of wire rod & light structural mills where the toughness and wear resistance of the rolls are critical for getting a good performance during use.

Traditionally SG Iron Rolls have the following properties –

High strength and toughness.

High wear resistance.

Higher gripping properties for better roll bite.

Resistance to fire crack propagation.

The graphite in the form of nodules significantly reduces the notch effect thereby improving upon the mechanical properties – one of the reasons they are considered one of the most versatile roll materials being the strongest among cast irons and having a strength comparable to steel.The SG Iron rolls are generally chill cast with the working surface having eutectic cementite and free graphite in spheroidal morphology. The addition of appropriate alloying elements in carefully adjusted combinations are practiced to get a wide range of matrix microstructure varying from the fine pearilte to Bainite or Accicular Martensite depending on the area of application of the roll precise inoculation & control of the rate of cooling during solidification allows the proportion of cementite to be reduced at the same time allowing an increase in the proportion of graphite nodules High tensile strength and deep hardness penetration are few properties that withstands heavy loads and hence these rolls are used in various mills that produce different products. Sufficient water cooling is a necessity for satisfactory performance.